The reconciliation of engine and wind propulsion

Adjustable propellers have been applied on marine vessels for decades. CPP is a suitable solution, for example, if reversing the propeller rotation direction is impractical due to the vessel’s size.

On yachts, the incompatibility of engine and wind propulsion can be a challenge. Propulsion by the wind, which is often uncertain, provides silence and pleasure, whereas noisy engine propulsion ascertains speed and comfort. In the past, due to a fixed propeller in the water, yachts with engine propulsion would be decelerated during sailing. The increased resistance of the vessel in the water would partially nullify the wind propulsion, leading to an unsatisfactory speed.

Moreover, despite the engine being off, the propeller would still be powering the shaft. This so-called “windmill-effect” produced a roaring sound on the backside of the yacht. The CPP is an advanced solution to improve the quality of sailing. Typically for the Controllable Pitch Propeller, the propeller pitch is infinitely adjustable from astern, via neutral, to ahead.

Several Scandinavian companies came up with the remarkable idea to position the propeller blade in a way to minimize resistance in the water during sailing, termed the “sailing position”. In this position, the propeller’s resistance in the water is almost negligible, which results in a non-existing windmill-effect on the shaft. When maneuvering with a CPP, the engine speed can remain constant at a comfortable speed, as enabling or disabling the gearbox is not necessary. Simultaneously, the motor power can be utilized for a hydraulic force on the bow thruster.

Due to our extensive knowledge and experience on the field of electronic control systems, the manufacturers of luxury yachts have asked us to develop an electronic single lever system that is capable of simultaneously controlling the engine, gearbox and Controllable Pitch Propeller. There was a need for a compact, safe, and reliable system that offers an electronic solution for operating at the steering position. We found an innovative solution to the hydraulic closed-loop control of the propeller’s pitch, and succeeded to combine this design with the user-friendliness and reliability of conventional control systems. The result is a reliable, compact, and robust control system which enables various control stations to be concatenated in different areas of the vessel. The system is built modularly and can be connected to all combinations of engines, gearboxes, and CPP units. Considering the wide variety of control levers, we assure that you will find a lever most suitable to fit the general atmosphere and design of your vessel. We use CAN J1939 (standard CAN protocol for engines), among others, to establish a direct connection with the engine ECU. This enables us to read the load of the engine and consequently calibrate the propeller pitch. All those systems meet the quality requirements of GL and Lloyd’s Register.

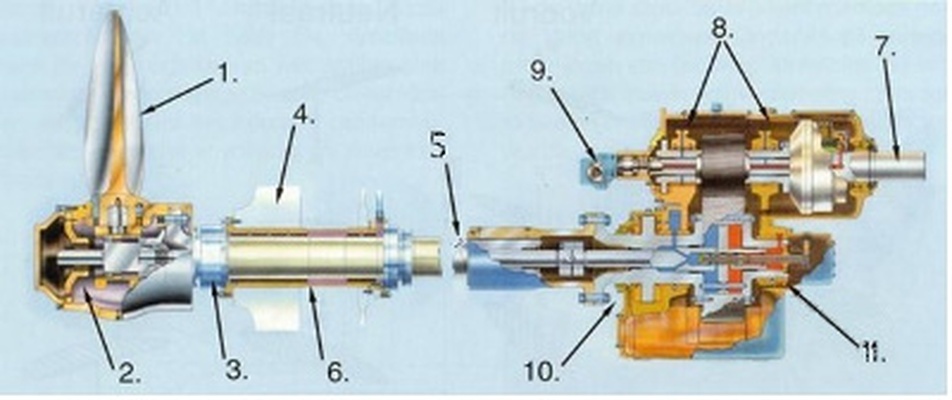

Specifications

- 1. Propeller blade

- 2. Flange

- 3. Watertight seal

- 4. Rudder

- 5. Propeller shaft

- 6. Stern tube

- 7. Engine shaft

- 8. Bearings

- 9. Mechanically-driven pump

- 10. Thrust bearing

- 11. Gearbox

Optionals

- n.a.